Double deep pallet racking is a storage system designed to store pallets two rows deep, one behind the other, effectively increasing storage density by about 30-40% compared to single-depth racks while maintaining reasonable access to inventory.

The double deep racking is a component of warehouse storage racking system. They are robust metal structures made up of beams that hold two pallet positions on the same level, all products uploaded by the LIFO(Last in, first out) module. It is often used in the middle of warehouse racking system to save aisle space in a cost-efficient way.

Higher Storage Density: By storing pallets two deep, it maximizes warehouse floor space and reduces the number of aisles needed, allowing more pallets to be stored within the same footprint.

Selective Access with Some Limitations: About 50% of pallets are immediately accessible from the aisle. To reach pallets stored in the second depth, the front pallets must be moved first, requiring special forklifts with telescopic or pantograph forks.

Requires Specialized Forklifts: Standard forklifts cannot reach the rear pallets. Double deep racking systems are used with reach trucks equipped with extendable forks or pantograph mechanisms to access the second pallet location safely and efficiently.

Robust Construction: Made from high-tensile steel with reinforced flanges and strengthening ribs to ensure safety, durability, and compliance with international standards.

Good Balance of Density and Selectivity: It offers a middle ground between selective pallet racking (high selectivity, lower density) and compact storage systems (high density, low selectivity), making it suitable for warehouses with moderate SKU variety and volume.

Adaptability and Reconfigurability: Beam levels can be adjusted, and the system can be converted back to selective racking if warehouse needs change, providing long-term flexibility.

Inventory Rotation: Operates primarily on a LIFO (Last In, First Out) basis for individual pallets, but can support FIFO at batch levels, depending on warehouse management

|

Product Name |

Double Deep Rack |

|

Material |

Q235B Cold-rolled Steel |

|

Product size |

Length: 2300 / 2500 / 2700 / 3000 / 3300 / 3600 / 3900mm Width: 900 / 1000 / 1100 / 1200mm Height: 2000-6500mm |

|

Thickness |

1.5mm, 2.0mm( column ) 0.6mm , 0.8mm (Beam) |

|

Load capacity |

800-5000 kg per layer |

|

Layers |

2-5 adjustable layers (can be custom-made) |

|

Color |

RAL color; As per customer's requirement |

|

Surface |

Acid-washing, Electrostatic spray surface |

|

Feature |

Anti-rust, Corrosion-protection |

|

Guarantee period |

5 years warranty |

|

Remark |

OEM&ODM accepted |

|

Relevant Certificate |

CE, ISO,ROHS |

|

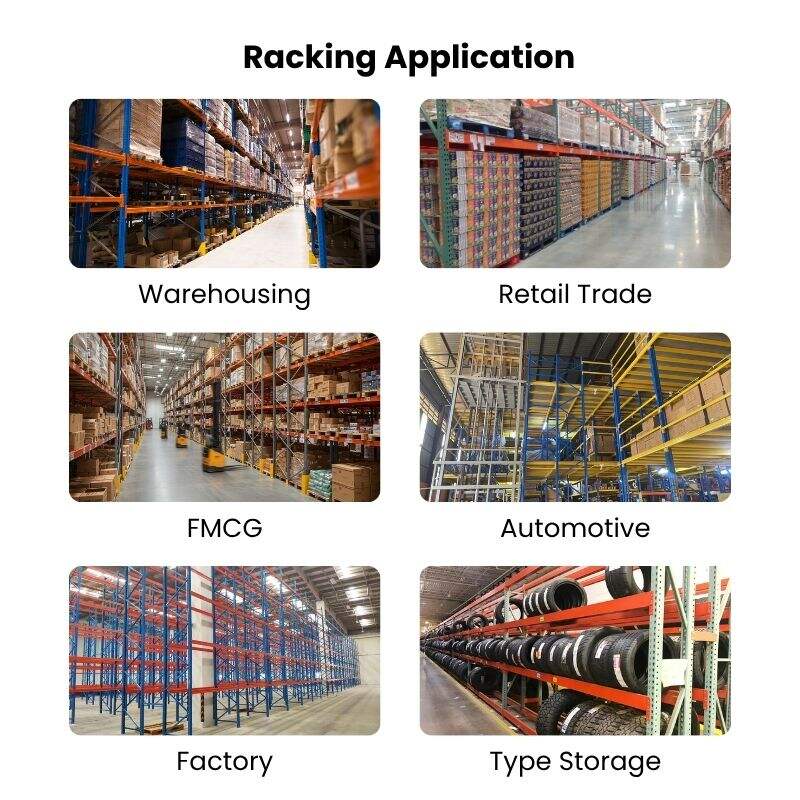

Use area |

Warehouse, factory, storage place |

|

Structure |

Knock down structure, easy assembling, convenient for delivery |

|

Function |

storage goods, rack, storage |

|

Product range |

warehouse, storage place |

Warehouses with multiple pallets per SKU: Ideal for storing large quantities of the same product, allowing efficient use of space by stacking two pallets deep.

Homogeneous or identical product storage: Suitable for businesses handling uniform stock where selectivity can be slightly compromised for higher density.

Medium to long-term stock storage: Best for products that do not require frequent rotation, as the system operates on a LIFO (Last In, First Out) basis, making it less suitable for highly perishable goods.

Operations with advanced stock management: Warehouses with robust inventory control systems that can manage restricted access to some pallets benefit from the increased storage capacity.

Retail distribution: Stores large volumes of fast-moving consumer goods efficiently, balancing storage density and accessibility.

Food and beverage industry: Used for both perishable and non-perishable items, improving inventory management and space utilization.

Automotive parts suppliers: Accommodates a wide range of products while optimizing warehouse space.

E-commerce fulfillment centers: Helps handle vast inventories by maximizing storage density without sacrificing too much selectivity.

Manufacturing and industrial storage: Stores raw materials, components, and finished goods, streamlining supply chain operations and improving efficiency.

Manual and automated warehouses: Compatible with both, requiring forklifts with telescopic or pantograph forks to access pallets in the second depth.

Q: Are you manufacture or trading company?

A: We are manufacture. Our factory has been specializing in supermarket shelves, warehouse racks and different,kinds of display stands since 2001.

Q: Where is your factory? Can I visit ?

A: Our factory is located in Foshan, Guangdong. You are warmly welcome to visit whenever you are available.

Q:What is your delivery time?

In general, within 15 days. It also depends on the order quantity and shelving design.

Q:What is your moq?

A:Depending on Your Project. We offer layout services and tailor-made solutions for your warehouse or store.

Q:What certificate do you have?

A:CE, ROHS,ISO:9001

Q: What is the term of payment?

A: Payment terms: 30% of deposit upon signing the PI, and balance will be cleared by T/T before delivery.

Q:What does HEDA Rack do?

A:At HEDA Rack, our mission is to provide one-stop storage solution for all commercial and business racking. We have 20+ years of experience in racking designing, manufacturing, installing, helping you to make the smartest choices when it comes to optimizing warehouse space. See our About Us page for more information.