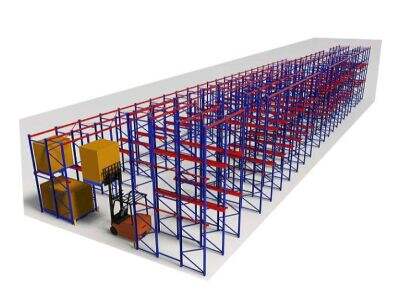

When establishing a new warehouse, or attempting to optimize one already functioning, your racking setup is of the utmost importance. A drive-in pallet racking suppliers like Heda is another option if you have a high volume of the same product that doesn’t have to be picked immediately. You are able to store pails of pallets deep which you can access using a forklift. But making sure this system goes according to plan can be fraught. You can always return if the shoe doesn’t fit, but it’s worth considering how much room you have to spare, what kinds of products you’re storing, and how frequently you’ll need to access them. Read on to see how you can create a drive in racking system that will cater to your needs.

Get the Most Out of Your Warehouse with Drive-In Racking

Drive-in racking is great for when you need more space. Because the racks are configured so pallets can slide in, you can shove them in as far as that rack will go. In other words, you can store more stuff in less space. But in order to truly maximize your space, it is worth considering how high your warehouse ceilings are, and using as much vertical space as you can. The racking system supplier like Heda’s drive-in racks are strong enough that they can go very high, enabling you to stack up and save those big swaths of floor.

Important Factors to Consider Print Designing a Drive-In Racking System

There are a few key concerns to address when you’re designing your drive-in racking system as well. The stuff you are storing: Big and heavy First, you need to take into consideration the size and weight of the stuff you are putting into your storage unit. Heda’s racks can take a lot, but you’ll want to check to make sure they’ll fit your products. Also, consider how often you will need to reach each of the pallets. Drive-in systems by industrial racking suppliers are great but only when you’re not pulling out stuff all the time, as it can be a struggle to access a pallet buried somewhere in the back.

Organising your Drive-In Racking system

Organizing your drive-in racking system can be difficult, but it is essential. One is a “last in, first out” (LIFO) approach. That means the last pallet in is the first one out. It even keeps things moving along harmoniously. Also ensure forklift drivers know how to work the system safely. You don't want any accidents.

How to design an efficient drive-in racking system

To maximize the efficiency of your drive-in racking system, it should be designed for productivity. This involves organizing the aisles and bays so that forklifts can get in and out efficiently. Also consider coloring or labeling things to make it easier for drivers to find what they are looking for more quickly. Heda can custom configure your racks so they are tailored to fit your warehouse perfectly.

Customizing Your Drive-In Racking to Match Your Warehouse Requirements

Each warehouse is unique, and therefore your drive-in racking solution should be customized to best suit your application. Consider where in your warehouse you would like to have the racks installed. You may need to modify the design to work around things like columns or doors. Heda’s staff can help determine the optimal setup for your space, so the system works just right for you.