Ultimate Guide For Mezzanine Rack

When you're replacing or installing your warehouse racking, you might wonder, how to get more space, save time& money. Warehouse mezzanine floor, also as industrial mezzanine, is a good choice for your needs, material, types, and Applications

This guide will walk through mezzanine types, capacity, installation costs and the key factors that affect the total cost to help you make the best choice.

What is Warehouse Mezzanine?

Warehouse Mezzanine is a type of warehouse storage equipment allows people picking or store Multi-SKU Product. It is an elevated platform or intermediate floor built within a warehouse or industrial facility. Its primary purpose is to maximize the existing vertical space by creating additional usable area between the main floor and the ceiling, without requiring a costly building expansion or relocation.

Types of Warehouse Mezzanine

There are many types of mezzanine floors, and each one has its own unique set of benefits. The first step to choosing the right type for your business is to understand what each one does.

- Shelving or rack-supported mezzanine floors

- Free-standing mezzanine floors (Mezzanine Platform)

- Catwalk Mezzanine Floors

- Cantilever Mezzanine

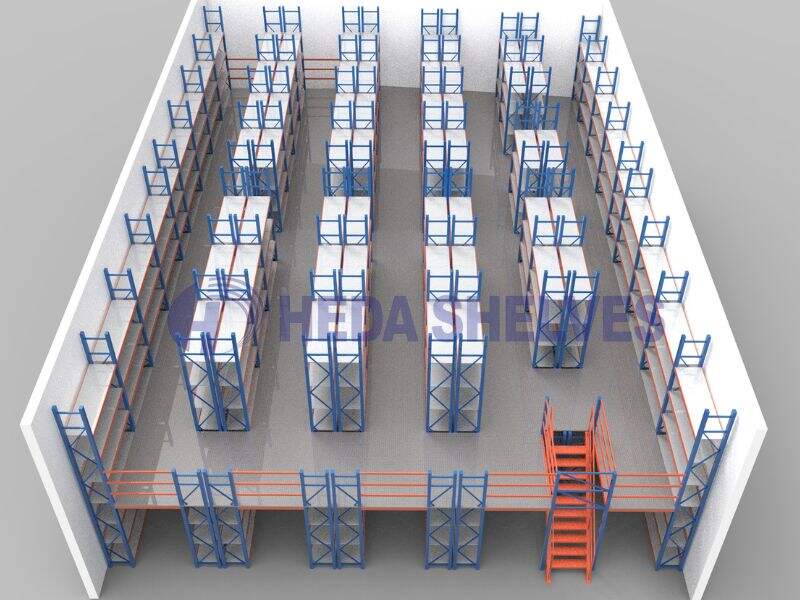

Shelving or Rack-Supported Mezzanine Floors

Shelving mezzanines are built directly on top of existing or new shelving or pallet racking systems. The shelving or racking itself acts as the primary support structure for the mezzanine deck above. As a Compact storage shelving system, rack-support mezzanine is a flexible solution adapt to your storage equipments.

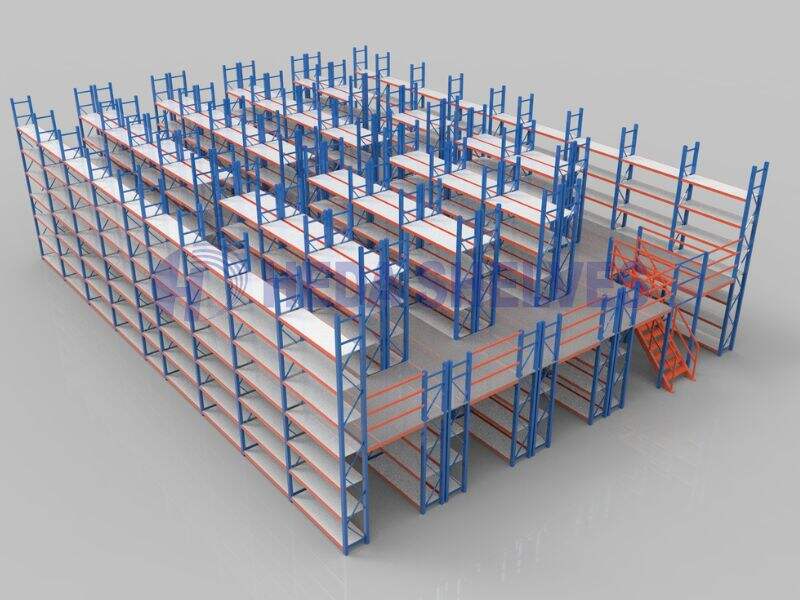

Free-Standing Mezzanine Floors (Mezzanine Platform)

A Free-Standing Mezzanine Floors is a prefabricated elevated platform or flooring system support 2-5 layers that easily assembled and disassembled. It is designed to create additional storage space in warehouses or industrial facilities, common support 1000KG/SQM.

It is commonly used for cost-effective and customizable solutions for adding storage space for light or medium bulk goods storage , allowing for future reconfiguration or relocation based on changing storage needs.

Catwalk Mezzanine Floors

A Catwalk Mezzanine Floors is a type of elevated platform or flooring system with narrow aisle that apply for racking system connect or platform cross. It is designed to optimize vertical space in warehouses or industrial facilities by adding a mezzanine level above the existing shelving.

Catwalk Mezzanine Floor can be customized to match the load capacity and configuration of the existing shelving, providing a seamless integration with other warehouse storage systems.

Cantilever Mezzanine

Cantilever Mezzanine is common used in building material warehouse that creates additional storage levels for long-term inventory. It is designed to optimize vertical space in warehouses or industrial facilities for pipes, tubes, timbers, furnitures.

It is commonly used for maximizing storage capacity, improving material flow, and integrating with other warehouse storage systems, such as conveyor systems or automated picking systems.

Application of Warehouse Mezzanine

Increased Storage Space: Mezzanines allow businesses to add multiple levels for storing inventory, equipment, and supplies, maximizing the vertical cube of their warehouse. This can include:

- Bulk storage: For items accessed less frequently.

- Archiving: For documents, records, or sensitive materials.

- Pallet racking and shelving: Expanding existing storage systems upwards.

- Seasonal inventory storage: Providing extra space for fluctuating demand.

Where Can You Apply Warehouse Mezzanine

Office Space: Mezzanines are ideal for creating new or expanding existing office areas within the warehouse. This allows for administrative, supervisory, or customer service functions to be located close to operations while remaining separate from the main floor's noise and activity. These can be open-plan or enclosed with climate control and soundproofing.

Production and Assembly Areas: Businesses can integrate new production lines or assembly stations on mezzanine levels, optimizing workflow and separating these processes from storage areas. Goods lifts and conveyors can facilitate the movement of items between floors.

Work Platforms: Mezzanines serve as elevated work platforms for various tasks such as packaging, order fulfillment, light manufacturing, or specialized maintenance areas.

Catwalks and Observation Decks: Narrow mezzanines, often called catwalks, provide safe pedestrian walkways for personnel to move between areas or access equipment for maintenance. Larger mezzanines can be designed as observation decks to oversee warehouse operations, enhancing supervision and security.

Staff Facilities: Mezzanines can house break rooms, canteens, changing rooms, and locker areas, providing dedicated spaces for employees away from the main warehouse floor.

Product Display/Showrooms: For businesses that host clients, a mezzanine can be an excellent location for product displays or demonstrations, keeping them separate from the daily operations.

Conclusion

Ready to get a cost-efficiency solution to the warehouse and enhance your picking efficiency? Explore the HEDA RACKING Warehouse Mezzanine. Upgrade your warehouse racking system today and Less Space, higher capacity!

FAQ

How does mezzanine racking differ from a mezzanine floor?

Mezzanine racking is more space-efficient and designed for lighter loads with manual access, offering higher storage density. Mezzanine floors generally have higher load capacities and are palletized, suitable for heavier loads and mechanized handling.

What is the typical load capacity of mezzanine racking?

Mezzanine racking systems are usually designed for medium-duty storage, supporting loads from about 300 to 500 kg per tier, In HEDA RACK, our mezzanine floor systems capable of up to 1000 kg per tier. They are suitable for units storage that are manually accessed. Contact Us Today.

Can mezzanine racks be modified or relocated?

Yes, mezzanine rack systems are modular and can be modified, expanded, or relocated to accommodate changing warehouse needs, providing flexibility as business requirements evolve.