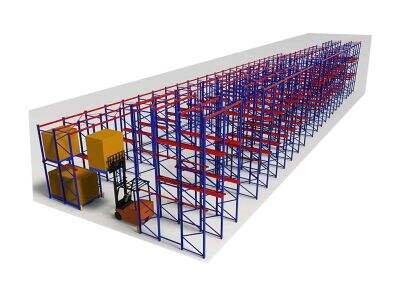

Narrow aisle racking is a clever technique for accommodating many things in a limited space. When companies design these racks, they are often considering how to take up space front-to-back and top-to-bottom, not just side to side. Which is to say you stack them higher, instead of spreading them wider. It’s building a tall tower — not a long line. Heda knows that smartly utilizing vertical space allows businesses to store lots and lots of products safely and in a way that its workers can quickly find them all rather than needing the equivalent square feet of dozens of single-story warehouses. It is an idea that fundamentally changes the appearance and functionality of warehouses, making storage better and smarter

Why you should consider using the vertical space to ensure cost efficiency of wholesale narrow aisle racking solutions

The Utilization of height cannot be overemphasized when it comes to turning narrow aisle racking into an economic and efficient storage system. When shelves climb high, you get to put more products there with less necessity for racks. This spares floor space, which invariably is expensive to rent or construct. Consider a store that does a lot of parts or boxes. If ultimately the shelves are only to go up a few feet, the store has to have a big building in order that everything may be accommodated. If those shelves go up right to the ceiling, the same building holds a lot more stuff. That means less money going into space, and a need for fewer racks. And, narrow aisles mean a forklift can easily move between racks without requiring wide paths. Everything is kept in tall racks with narrow aisles, where inches count. Take Heda’s racks, which are engineered to remain seated and stable so all but the heaviest of items can be stored with minimal worry. The racks are constructed with durable steel and their thoughtful designs make them capable of holding a lot of weight. This enables warehouses to buy fewer extra support beams or walls, saving them even more money. Sometimes people fear that tall racks are difficult to use or unsafe. But Heda constructs racks that are readily accessible with special forklifts and safety features. There are, and productive ones: workers can easily reach high shelves, with no risk to themselves. It also saves companies from spending money on special machines or training workers. By stockpiling, businesses minimize the time spent walking and moving. Items are found faster, allowing workloads to stay on track. That saves money on labor (a huge part of warehouse costs). And so, capitalizing on vertical space isn’t just efficient in terms of buildings and racks; it also saves worker time and injuries. Businesses have a single, strong, secure and inexpensive place to store product. Which is why concentrating on height makes sense with narrow aisle racking

Where to Get Top-of-the-Line Narrow Aisle Racking Systems for Vertical Storage Utilization

Great slim aisle racking that uses upright area appropriate could be difficult towards discover. Certainly not all of shelfs are actually produced equivalent, as well as a couple of don't bear a lot value or even final lengthy. Exactly just what establishes Heda apart is actually that right below our team style shelfs based upon cautious ideas as well as abilities towards carry the required real support in the storage facility. Our shelfs are actually developed to prevent hefty loads safely also at greater degrees. We understand exactly how aggravating it is actually when shelfs flex or even break after months of utilization. That's why our team utilize the very best products as well as examine every rack manually in our very personal manufacturing facility. Various other shelfs might appearance good, however go weaker at the knees if you put a lot of hefty packages in all of them. Heda's racks don't simply seem sturdy; they are actually durable. And also, our shelfs are actually developed for slim aisles anyhow. We consider exactly how forklifts relocate as well as exactly how employees get points. That implies that racks are actually located to ensure that employees can easily get things easily without needing to climb up or even extend as well much. Our team likewise help clients in identifying one of the absolute most appropriate height for their area. Sometimes, a shelf that is as well tall or brief can easily decrease jobs or even use up area. Our team are actually possessing discussions along with customers towards accomplish that balance." The various other point that makes Heda unique is actually our team perform complete solution. Coming from developing the design, producing the shelfs, towards delivering and establishing our team exist. This is just one of my secrets that conserves cash or even opportunity

Typical Problems in the Management of Vertical Space for Narrow Aisle Racking Manufacturers

When it comes to narrow aisle racking, the utilization of space up and down, or vertical handling space is critical. But controlling this vertical space can be difficult, especially for manufacturers like Heda. One of the big challenges is ensuring that the racks are strong enough to hold heavy items stacked high. Weak racks can also bend or break, which is both unsafe and expensive. Another challenge is safety. As racks stretch very high, workers must use special tools to reach the top shelves, like forklifts. This can be dangerous, if the racks are not erected properly or if the amount of space is insufficient for the forklifts to maneuver without causing damage. What’s more, narrow aisles leave less space for both machines and workers to maneuver, forcing manufacturers to design racks that fit well but don’t make the aisles particularly cramped. And finally, using vertical space well equates to ensuring that every inch of is utilized and not a square inch goes wasted. Some racks are too tall because how they use the space doesn’t make sense due to a poor design. Heda puts a lot of work into solving these problems, thinking hard about how high the racks need to be, how strong they should be, and how workers will operate safely in the space. These challenges demonstrate why focusing on vertical space isn’t just about stacking higher, but doing so in a smart and safe manner

When Space Savings and Racking Strength Are What You Need in Your Narrow Aisle Racks

Heda understands that great use upright area implies shelfs that final a very long time as well as are very resilient. If the shelfs are actually likewise high as well as slim, which they typically are actually, after that they need to have the ability to carry a hefty tons without toppling over or even flexing. That is why Heda is actually dedicated towards solid products as well as fantastic style for protecting shelfs as well as guaranteeing that they stay durable. Utilizing upright area effectively is actually likewise one method shops as well as warehouses can easily keep much a lot extra items in less flooring area. That's less expensive, because the structure doesn't have actually to become bigger. However saving space is actually just great if the shelfs do not breather or even produce mishaps. Which is actually why Heda develops shelfs that are actually solid as well as reliable, therefore employees can easily depend on all of them every day." Another element of upright area usage is actually creating it simple for devices towards accessibility the racks. Heda is actually although creates shelfs that function efficiently with forklifts as well as various other devices, also in limited aisles. This accelerates as well as creates the procedure of placing items on racks as well as taking them off also quicker as well as much more secure. Through producing racks that are actually each difficult as well as easy towards utilize in restricted areas, Heda assists business make the most of their storing locations. The blend of area conserving as well as lasting shelfs belongs to the reason why a lot of clients depend upon Heda for their slim aisle racking

Combat Typical Problems When Installing Vertical Narrow Aisle Racking Systems

It can be somewhat difficult to install high narrow aisle racking system, but Heda has good solution methods for the problems that arise generally. One challenge is ensuring that the floor is strong and level enough to support the weight of heavy racks. If the floor is not level or otherwise weak, the racks may not stand straight and might come crashing down. To avoid those surprises, Heda checks the floor carefully before beginning installation and occasionally will assist customers in repairing the floor first. Another challenge is squeezing racks into small spaces without interfering with aisles or making it difficult for machinery to maneuver …. Heda carefully plans the layout, measuring the space and considering how forklifts and workers will move around. This advance planning helps prevent the space from becoming too crowded and ensures that everything is running in good working order. Parts of the rack sometimes had to be assembled up high, which was not only dangerous but also time-consuming. Heda has trained its installation team in the safe use of specialized tools and safety rules. And finally, after the racks are installed, Heda makes certain everything is tested and locked in. This last inspection is a safeguard against any issues before the racks are put into use. "Doing so, Heda assist customers in utilizing their vertical narrow aisle racking systems optimally, and safely." This thoughtful strategy simplifies installation and allows businesses to execute the best use of their space

Table of Contents

- Why you should consider using the vertical space to ensure cost efficiency of wholesale narrow aisle racking solutions

- Where to Get Top-of-the-Line Narrow Aisle Racking Systems for Vertical Storage Utilization

- Typical Problems in the Management of Vertical Space for Narrow Aisle Racking Manufacturers

- When Space Savings and Racking Strength Are What You Need in Your Narrow Aisle Racks

- Combat Typical Problems When Installing Vertical Narrow Aisle Racking Systems